3D Printing Service with Polypropylene (PP)

PPprint Printing Service

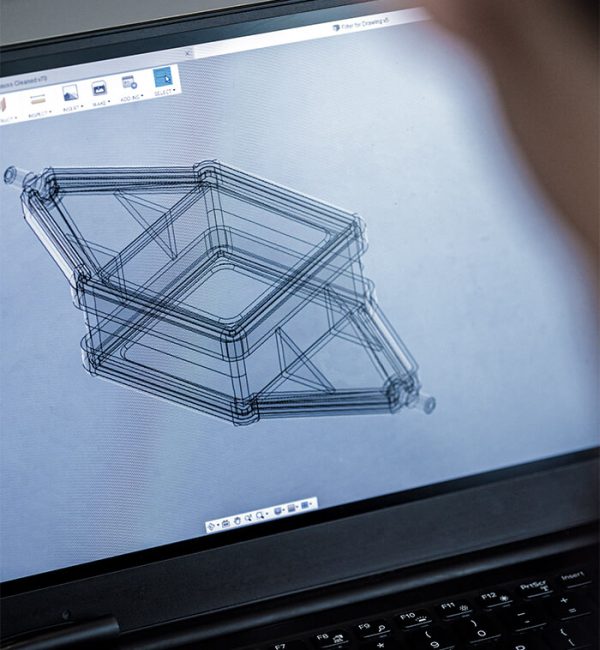

Design & Construction

Develope sophisticated PP components jointly with PPprint. Realize your 3D designs and constructions according to your ideas. With our experience and possibilities, almost all geometries can be realized with the material polypropylene.

Our Services:

- 3D scanning of models

- Creation of CAD files

-

Creation and preparation of STL files

for 3D printing

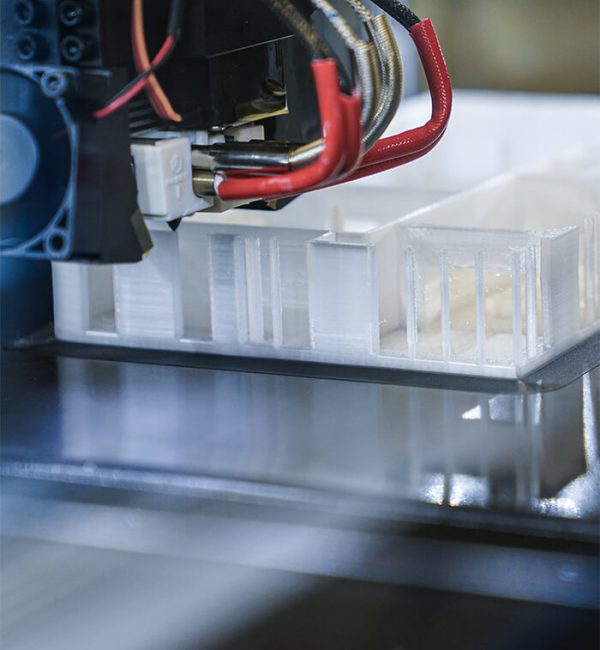

Manufacturing

PPprint manufactures components with PP using extrusion-based 3D printing. Our application team offers you individual technical support and advice. With our expertise we optimize your products to the highest quality. Your product data will always be treated confidential.

We offer:

- Production of components made of polypropylene

- Rapid prototyping, one-off production

- Small series production

Expertise

The PPprint team has many years of experience in the field of additivation, processing and application of polyolefins. With this know-how we support our customers in extrusion-based 3D printing with polypropylene. Under one roof we combine material development of PP filaments, a broad experience with different 3D printers, design and construction of PP parts and contract manufacturing of PP products.

Benefit from us:

- Consulting and technical support

- Individual trainings

- Workshops and events

Advantages of polypropylene

Due to the low density of PP it is perfectly suited for the fabrication of lightweight 3D printed products.

PP is a sustainable material because it is fully recyclable.

3D-printed products made of PP withstand mechanical stress very well, as PP has a high breaking strength.

3D printed PP products can be tailored to the requirements of a wide variety of applications due to the semi-flexibility of PP.

PP is perfectly suited for applications in contact with almost all chemicals and solvents as a result of its outstanding chemical resistance.

Polypropylene components are optically appealing and show a high surface quality.

Polypropylene can be used in contact with food and is food-safe.

Products made of PP are dishwasher safe and can be easily cleaned.

Polypropylene is highly suited for contact with water. PP is not moisture sensitive and PP filaments has not to be dried prior to 3D printing.

Products made of PP can be prepared in different colors by using colored filaments.

3D printed parts made of ‘P-fialment 721 natural’ are certificated according DIN EN ISO 10993-5 for biological safety and therefore skin-friendly.

With ‘P-support 279’ the first breakaway support material especially developed for polypropylene is now available.

Our areas of application

Polypropylene (PP) is ideally suited as a material for technical and medical applications due to its balanced property profile. The combination of mechanical strength and flexibility make PP ideal for 3D-printing. The low density of PP also means that lighter parts can be produced that are both strong and robust. The mechanical properties, the low density, and in addition the outstanding chemical resistance to substances such as acids, bases, alcohols or water makes PP ideally suited in a wide range of applications in different industrial sectors.

Automotive

PP is already an essential component in the automotive industry. 3D printing of PP can complement classic manufacturing processes such as injection molding or extrusion to optimize and further develop the application portfolio. PPprint sees the main potential of 3D printing with PP in the automotive industry in the rapid production of prototypes and development components to efficiently optimize products for series production. In this way, components can be manufactured in early development stages in the material that has a very similar property profile to the end-use material.

Exemplary applications:

Waterproof tanks, ventilation ducts, clips, …

Medical Technology

The material PP has proven its suitability for medical technology applications to the highest degree in the last decades. For applications as orthoses or orthopedic aids, the combination of break resistance, semi-flexibility, low density as well as the possibility of sterilization and easy cleaning is ideally suited for 3D printed PP products. As a result, individually manufactured PP products increase the wearing comfort and improve the healing process.

Exemplary applications:

Orthoses, positioning splints, connecting elements, individualized adaptation, standing or sitting assistance devices, …

Architecture, Art, and Fashion

3D printing is becoming increasingly important in today’s highly customized industries. Depending on the application, different properties of polypropylene, such as translucency or breaking strength, may be of interest. With polypropylene, there are no limits to the designer’s ability to create a highly customized part for real-world use.

Exemplary applications:

Break-resistant architectural models, lamps or illuminated elements, individualized decorative elements, …

Further industries

Polypropylene is by no means restricted to one specific industry or industrial sector. The balanced property profile can be beneficially used in manifold applications. If you are interested, please contact us for a free initial consultation for your specific application.

Further application fields:

– Sports and Lifestyle

– Food Industry

– Filter Industry

– …