Description

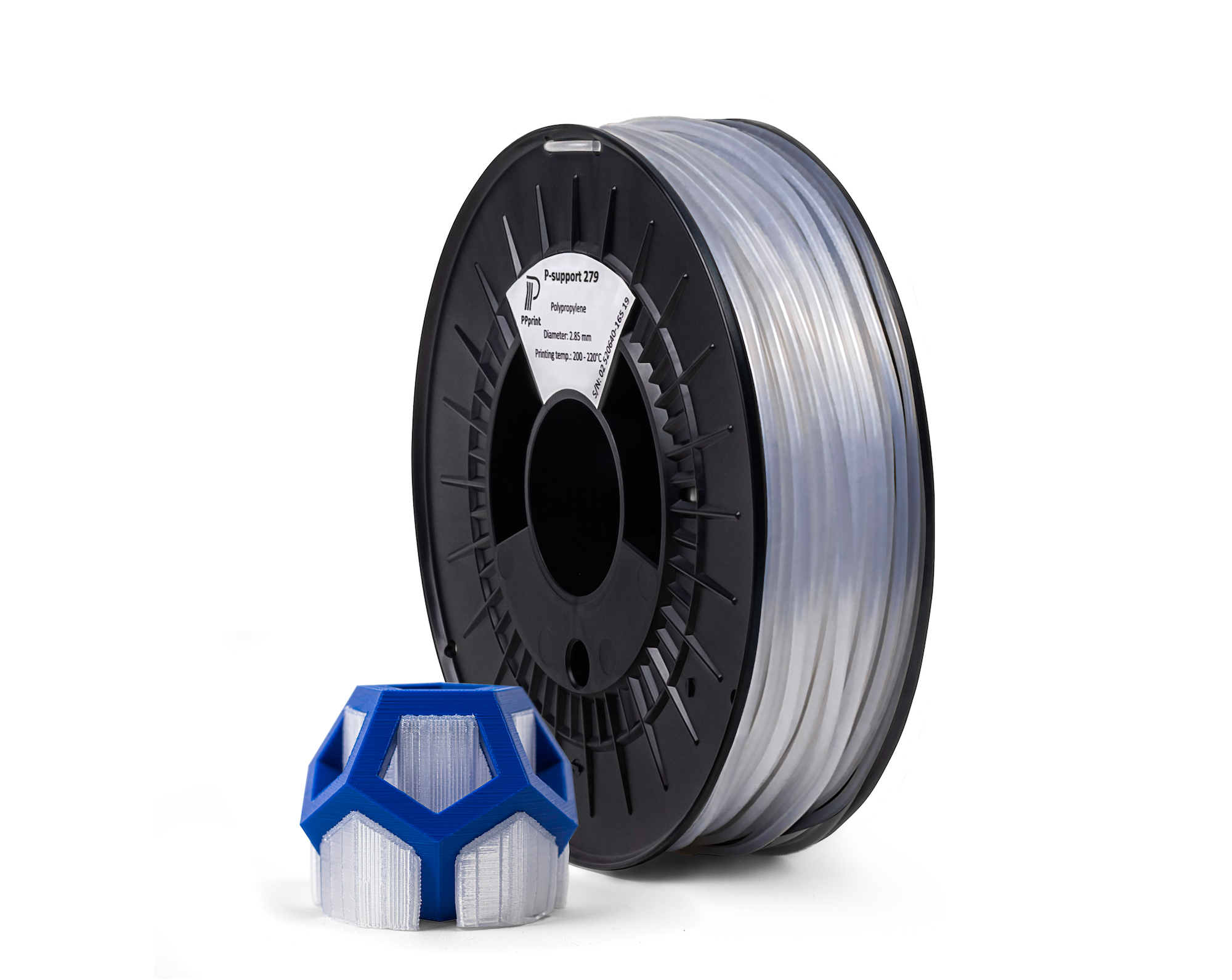

‘P-support 279’ is the world’s first breakaway support material specially developed for polypropylene, which allows the extrusion-based 3D printing of even more detailed and complex structures with bridging, overhangs and openings ‘P-support 279’ features high stiffness, low warpage and excellent adherence to the printed PP part and to the ‘P-surface 141’ 3D printing build surface. Therefore it is also ideal for producing rafts or support structures on printed PP. ‘P-support 279’ can be removed cleanly and easily from the printed part after heating to 100°C. A breakaway support material also has the particular advantage that no polymer waste containing solvents or water is produced. The breakaway thermoplastic support material ‘P-support 279’ is easily recyclable, making extrusion-based 3D printing with PPprint materials extremely sustainable.Pre-treatment of ‘P-support’: ‘P-support 279’ requires no drying before 3D printing and can be used without any pre-treatment.

Recommended printing parameters:

- ‘P-surface 141′ is required as 3D printing build surface

- Extruder temperature: 200 – 220 °C

- Printing bed surface temperature: 20 °C (50 – 70 °C during the first layer, 100 – 110 °C for non-destructive removal after completion)

- Installation room temperature: not necessary

How to remove the support material ‘P-support’ from the printed PP part: After extrusion-based 3D printing, ‘P-support 279’ adheres extremely strongly to the printed PP part and the ‘P-surface 141’ 3D printing build surface. Caution hot! Wear protective clothing and gloves to prevent burns. By heating ‘P-surface 141’ to 100 – 110 °C, the bottom ‘P-support 279’ layers become soft like chewing gum, so that the printed part and support structures can be removed non-destructively at this temperature. To remove ‘P-support 279’ printed further up in the part, the part with the adhering ‘P-support 279’ can be heated in an oven to 100°C or by immersion in boiling water. As soon as ‘P-support 279’ is completely heated up to 100°C, it can either be peeled off the 3D printed part immediately hot (protective clothing required) in its present chewing gum-like state or removed after cooling and solidification. The hot chewing gum-like state of ‘P-support 279’ also allows deforming and thus pulling out support structures which have been printed in openings or holes and have to be pulled or pressed through slightly smaller openings for removal. After the complete removal of the supporting material ‘P-support 279’ the PP component can be used. Storage instructions: To ensure consistent print performance, ‘P-support 279’ should be used and consumed as soon as possible after opening (preferably within 15 months). It is recommended to store opened material at a temperature of 15 – 25°C and in a plastic bag to avoid dust contamination.

Disclaimer

The product is designed as a support material for extrusion-based 3D printing with PP and is not developed and optimized for a specific purpose of a printed object. Not every object can necessarily be printed with ‘P-support’. It is your sole responsibility to always verify that all objects printed with ‘P-support’ are suitable, safe, and efficient for their intended use. This is particularly valid in view of the fact that the physical and mechanical properties and thus the dimensional stability of the objects are limited and the 3D printed parts and its properties may persist only for a limited period of time. In extrusion-based 3D printing, the material and manufacturing method are crucial to the performance of the printed object. A 3D printed object or part may appear identical to a commercially available analogue, but may behave differently for a variety of other reasons. PPprint GmbH assumes no liability for problems of this or similar nature. It is also your sole responsibility to ensure that the printed object does not violate any laws or infringe the intellectual property rights of third parties, such as patents, company or product identities, trade names, company names, logos, designs, utility models or copyrights. In addition, ‘P-support’ may not be used for products in construction, medical or other areas that are subject to legal regulations or have an increased risk potential. ‘P-support’ may absolutely not be used for the production of any kind of weapons. P-support has been tested on several different 3D printer models. However, PPprint GmbH cannot guarantee compatibility with all available 3D printer models. Again, the customer is solely responsible for ensuring that ‘P-support’ is always installed, used and stored according to our recommendations. If a customer complains within the warranty period that the product is defective, but after a corresponding examination by PPprint GmbH it turns out that a product is not defective, PPprint GmbH reserves the right, at its own discretion, to charge the customer for the costs incurred by PPprint GmbH for work and expenses in connection with these examinations. The amount of the costs shall be determined on the basis of the prices of PPprint GmbH valid at that time.