PPprint GmbH has developed and launched on the market an innovative combination of a PP filament and a printing bed support for extrusion-based 3D printing of PP.

PP is currently hardly used in 3D printing due to its poor adhesion between the layers and to the printing bed. PPprint GmbH has the solution! With the specially developed PPprint Starter-Kit everyone can now easily and successfully print 3D with PP.

“We achieved the breakthrough by solving three challenges. First, our p-filament has been optimized with regard to reduced warpage, high layer adhesion and very good mechanical properties. Secondly, we have developed an ideal pressure bed support on which PP components adhere optimally. Thirdly, the components can be removed easily and non-destructively after completion,” says Managing Director Dr. Christian Neuber, who is responsible for technical development and production.

The PP objects and components printed with ‘P-filament’ in 3D are extremely durable, versatile and very break-resistant. They have high hardness, toughness, low frictional resistance, high temperature stability and outstanding chemical resistance. Due to its low density, PP is also excellently suited for lightweight construction.

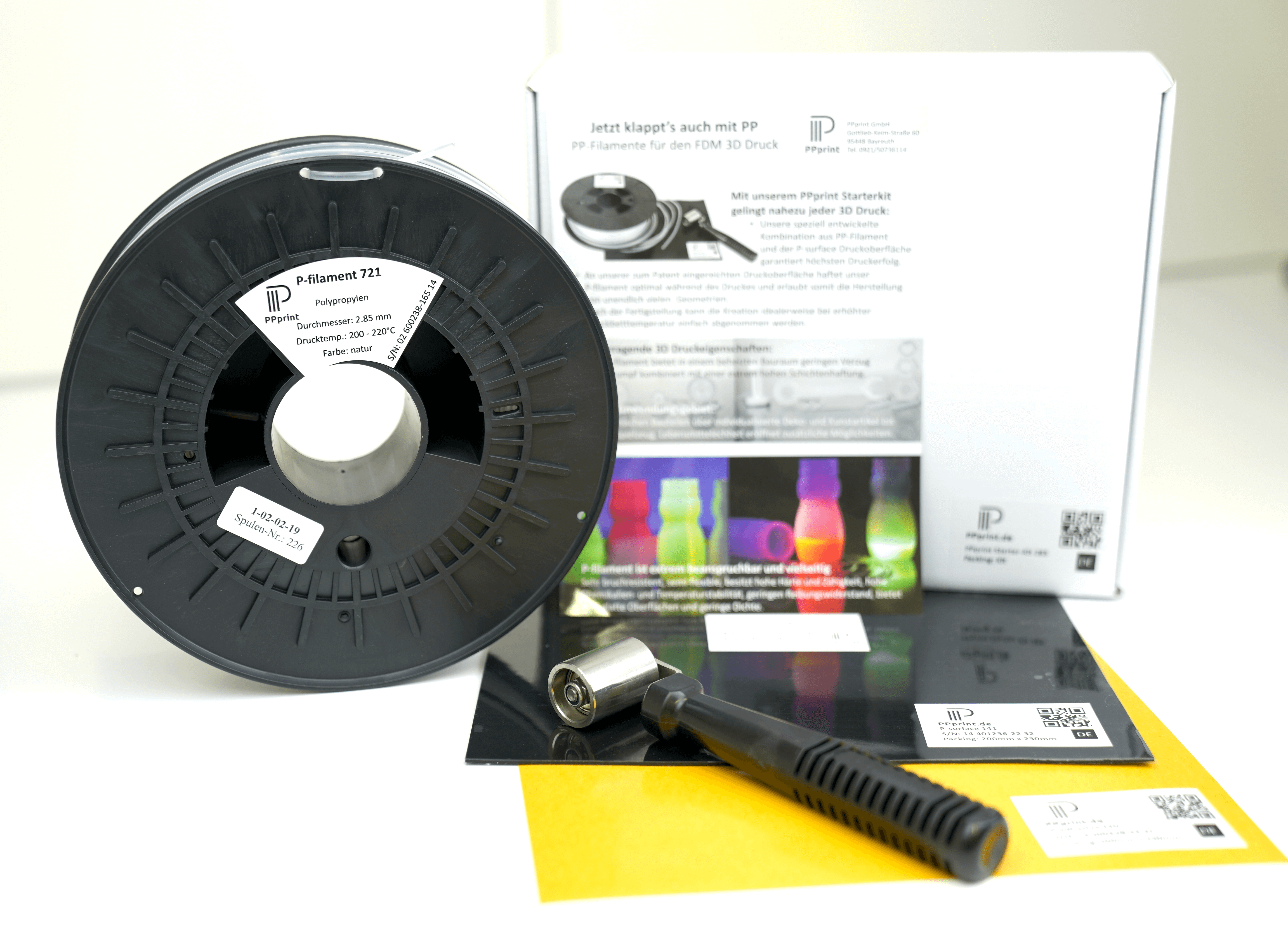

An easy start with the PPprint Starter Kit

With the PPprint Starter Kit we have put together everything that is needed for the successful 3D printing of PP. This is a big step towards establishing PP in the field of additive manufacturing,” says Dominik Walthierer, Managing Director for Marketing and Sales Management at PPprint GmbH.

The original report was published on 3druck.com as a press release by PPprint GmbH.